The Role of Foam Control in Enhancing Item High Quality and Effectiveness

Foam control is an often-overlooked yet crucial component in the pursuit of product high quality and operational effectiveness throughout varied industries. This discussion will discover the diverse impact of foam on both item stability and manufacturing procedures, increasing crucial questions concerning the strategies that can be utilized to enhance foam control.

Understanding Foam Development

Foam formation is an intricate sensation that can significantly impact product top quality and operational performance across numerous markets. Recognizing these variables is vital for taking care of foam properly.

The liquid's thickness and surface area tension play crucial functions in foam stability. Surfactants, as an example, can reduce surface area tension, advertising bubble development however also boosting foam security, which can be bothersome in certain applications. Mechanical anxiety, temperature level fluctuations, and the existence of pollutants can exacerbate foam generation, making it essential to keep track of these aspects throughout production procedures.

Industries such as food and drink, pharmaceuticals, and chemical production have to be specifically attentive concerning foam control. By comprehending the hidden devices of foam formation, organizations can apply targeted approaches to alleviate its impacts, thereby protecting operational efficiency and ensuring constant product performance.

Effect On Product Top Quality

The presence of foam can considerably endanger item top quality across numerous markets. In producing processes such as food and drink, drugs, and cosmetics, excessive foam can bring about irregular product formulas. As an example, in food manufacturing, foam might trap air, impacting appearance and flavor, which can ultimately modify customer assumption and fulfillment.

Additionally, foam can impede the harmony of paints and finishings, resulting in problems like bubbles and uneven surfaces. In pharmaceutical applications, foam can disrupt the precise application of fluid drugs, possibly affecting restorative efficiency and patient safety. These high quality problems not just reduce the end product's allure however can likewise bring about pricey recalls and damages to brand name reputation.

Additionally, the existence of foam can complicate quality assurance actions, making it tough to accomplish consistent outcomes and exact dimensions. Effective foam control not just alleviates these dangers but likewise improves overall item quality by guaranteeing that formulations satisfy strict market criteria. By buying foam control approaches, business can safeguard their products, enhance client fulfillment, and maintain an affordable side in the industry.

Functional Difficulties From Foam

Efficient operations in various sectors can be drastically interfered with by the visibility of foam, which postures numerous difficulties throughout production processes. Foam can hinder mixing and response times, impeding the efficiency of chemical procedures. In markets such as food and drink, foam development can bring about imprecise fill degrees, causing product waste and incongruities in packaging.

In settings where health is extremely important, such as drugs and food handling, foam can complicate cleaning protocols, creating covert tanks for impurities. This not just elevates quality problems yet additionally can result in compliance concerns with Your Domain Name regulative criteria.

Additionally, the mental effect on operators can not be ignored; extreme foam can produce a disorderly work atmosphere, causing decreased morale and productivity. In summary, dealing with the functional difficulties postured by foam is important to keeping effectiveness and product top quality in numerous sectors.

Approaches for Efficient Foam Control

Exactly how can markets efficiently mitigate the obstacles presented by foam? Efficient foam control approaches are necessary for improving product high quality and functional performance.

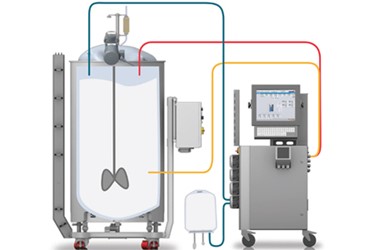

In addition to chemical solutions, procedure optimization plays a crucial duty in foam management. Industries can evaluate and readjust specifications such as mixing stress, temperature, and rate to lessen foam generation. Applying tools modifications, like setting up foam-breaking gadgets or adjusting container layout, can additionally help reduce foam degrees.

Normal surveillance and evaluation of foam actions within manufacturing procedures are likewise important. Using advanced sensors and analytics can provide real-time data, permitting timely interventions and modifications. Team training is equally crucial; making sure that workers are experienced regarding foam characteristics and control methods can lead to proactive foam administration.

Instance Researches and Industry Applications

While numerous industries encounter special difficulties related to foam control, study expose that tailored techniques can considerably improve both product high quality and functional effectiveness. In the pharmaceutical industry, for instance, a leading supplier applied a custom foam control technique that decreased foam formation during fermentation procedures. This innovation not just enhanced return by 15% but also lessened contamination risks, guaranteeing greater item stability.

In a similar way, in the food and drink market, a major milk manufacturer faced extreme foam throughout pasteurization - Foam Control. By introducing a specialized antifoam representative, they decreased handling time by 20%, which directly equated to boosted throughput and minimized click for more info energy usage. The application of foam control determines ensured constant product appearance and preference, strengthening brand name loyalty

In the chemical production market, a case study highlighted the successful application of foam control in wastewater therapy procedures. The implementation of a real-time surveillance system permitted drivers to readjust antifoam dosage dynamically, causing a 30% reduction in chemical use and boosted effluent quality.

These study illustrate the varied applications of foam control across sectors, highlighting its essential role in enhancing item quality and operational effectiveness.

Conclusion

In conclusion, effective foam control is integral to boosting item top More Bonuses quality and operational efficiency throughout different sectors. By resolving foam development, services can alleviate the adverse effect on solutions, texture, and dosing accuracy. Carrying out targeted foam administration methods not only lowers handling delays and waste yet also reinforces tools reliability. Ultimately, focusing on foam control contributes to enhanced efficiency, securing brand credibility, and boosting consumer fulfillment, highlighting its importance in quality control within producing processes.

Foam control is an often-overlooked yet crucial component in the quest of product high quality and operational effectiveness across varied markets. Staff training is similarly crucial; ensuring that employees are experienced about foam characteristics and control techniques can lead to positive foam monitoring.

While lots of sectors face unique difficulties connected to foam control, instance research studies reveal that tailored techniques can significantly improve both item top quality and functional efficiency (Foam Control). In the pharmaceutical market, for instance, a leading supplier carried out a custom foam control approach that lowered foam development during fermentation procedures.In verdict, effective foam control is indispensable to improving product quality and functional effectiveness across various markets